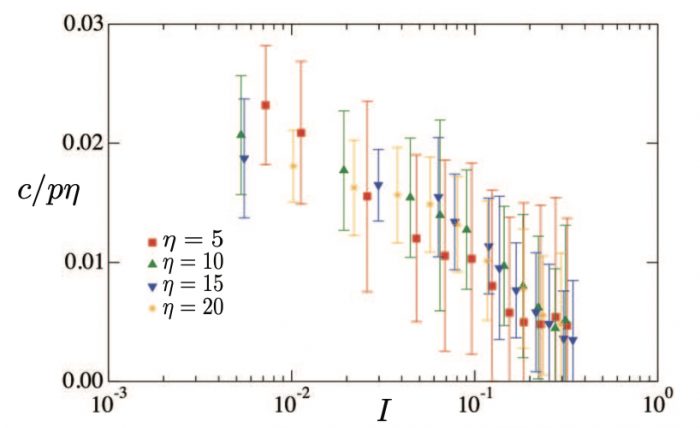

The action of interparticle adhesion forces f_c, irrespective of their origin (capillary bonding, van der Waals surface forces, …), endows granular flows with a cohesive strength in addition to the generic frictional strength that stems from friction forces and inelastic collisions between particles. In quasi-static flow regime, the shear strength of cohesive granular materials is classically expressed by the relation τ =µ σ +c, where µ is the effective friction angle, σ is the normal stress, τ is the shear stress, and c is the Coulomb cohesion of the material. According to this definition, the Coulomb cohesion c can be measured as the value of the shear stress at vanishing normal stress. In inertial flows, the friction coefficient μ is an increasing function of the inertial number I. What about c? Extensive simulations with a broad range of values of both the adhesion force and inertial number show that c is a decreasing function of the inertial number, and the apparent friction coefficient τ/σ is a unique function of a modified inertial number I_c in which σ is replaced by a linear combination of σ and f_c/d^2, where d is particle diameter.

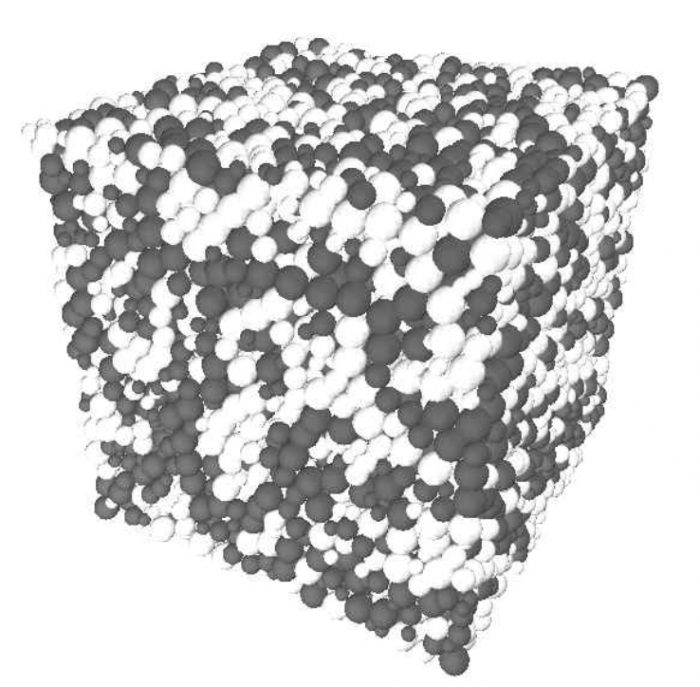

Compressive and tensile forces in a 3D packing of particles simulated by V. Richefeu.

Decrease of cohesion with increasing inertial number in a sheared packing.

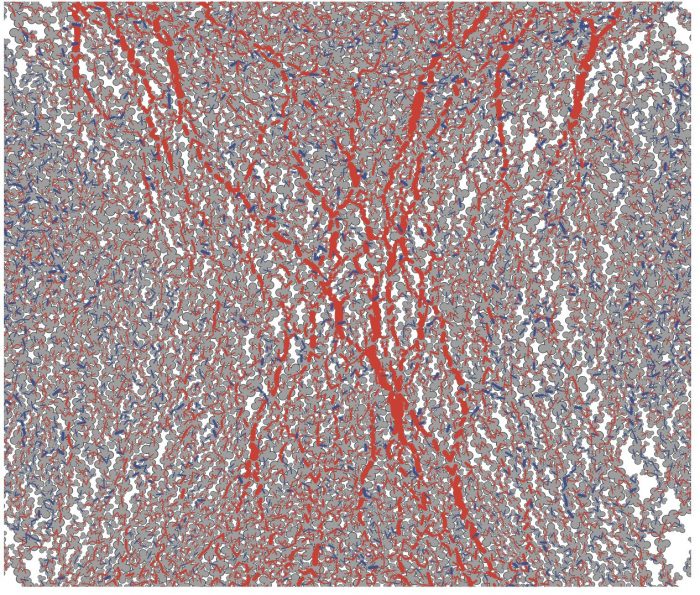

In various configurations, numerical simulations also show that the (macroscopic) cohesion is a linear function of the adhesion force with a prefactor that depends on the microstructure. This increase of cohesion reflects the extra anisotropies (in addition to those induced by friction) of the granular texture and force networks. An interesting feature of sheared cohesive granular materials is that the tensile forces play the same role with respect to the overall shear strength of the material as the weak compressive forces, both supporting or stabilizing the strong compressive force chains.

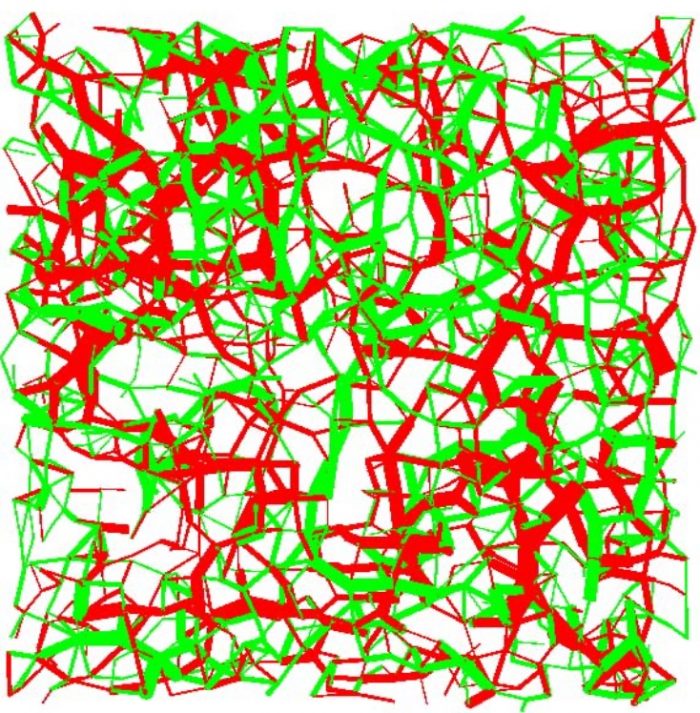

Force chains in a packing of cohesive nonconvex particles subjected to biaxial loading. Simulation by B. Saint-cyr.

Particles supporting positive (compressive in white) and negative (tensile in gray) mean stress in a sheared cohesive packing. They form two percolating networks across the system. Simulation by V. Richefeu.

Further reading:

Cohesive granular materials composed of nonconvex particles

Shear strength properties of wet granular materials

A model of capillary cohesion for numerical simulations of 3D polydisperse granular media

Stress transmission in wet granular materials

Additive decomposition of shear strength in cohesive granular media from grain-scale interactions

Bond anisotropy and cohesion of wet granular materials

Self-stresses and crack formation by particle swelling in cohesive granular media

Wheat endosperm as a cohesive granular material

Scaling behaviour of cohesive granular flows

Compressive strength of an unsaturated granular material during cementation

From liquid to solid bonding in cohesive granular media

Force transmission in cohesive granular media

Microscopic features of cohesive granular media

Static states of cohesive granular media

Mechanical strength of wet particle agglomerates

Strength of wet agglomerates of spherical particles: effects of friction and size distribution