The physical basis of the frictional properties of dense granular materials, studied first by Coulomb over two centuries ago coulomb, is still an open question. The frictional resistance inside a (dense) granular system or along a solid surface is a collective process involving the disordered network of interparticle contacts. In other words, due to kinematic correlations, the particles do not contribute independently to the overall friction. These correlations appear not only as a result of the multi-contact nature of a dense granular system, but also from the possibility of particles to roll over one another. At such nonsliding contacts no dissipation takes place. Moreover, according to Coulomb’s law of friction, the friction force T at a nonsliding contact is only partially mobilized, i.e. it takes an absolute value between zero and the product of the coefficient of friction µ and the normal contact force N. Only at sliding contacts, the friction force is fully mobilized: T=-µ N. For these reasons, the global frictional resistance is not a simple function of the interparticle coefficient of friction. It depends on the distribution of sliding and nonsliding contacts in the medium and on the highly heterogeneous distribution of contact forces, as observed in experiments and numerical simulations.

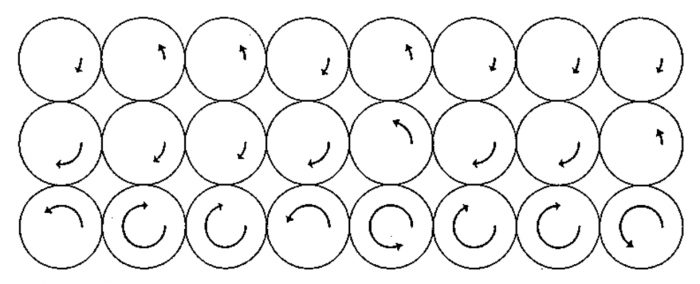

Rotation modes in a regular array of particles sheared by the horizontal motion of a basal plane.

If all particles could roll over one another, a granular assembly would deform without resistance, in contrast to the fact that a finite force is needed to trigger or to maintain a granular flow. Hence, the resistance of a dense granular system results essentially from the frustration of particle rotations. This means that, due to kinematic constraints, all contacts cannot all be simultaneously nonsliding. Consider, for instance, three identical disks mutually in contact. If the particles in this simple configuration rotate, then at least one of the three contacts has to be sliding. The patterns of rotational frustration are generally much more complex and need a systematic study if a fundamental understanding of the mechanisms of friction in granular systems is to be gained.

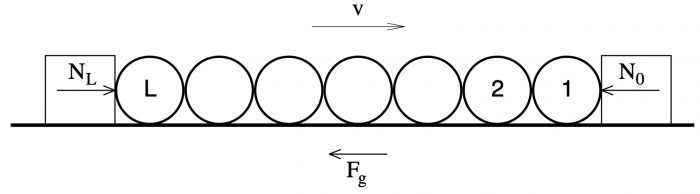

A 1D array of cylinders pushed by an external horizontal force along the basal plane.

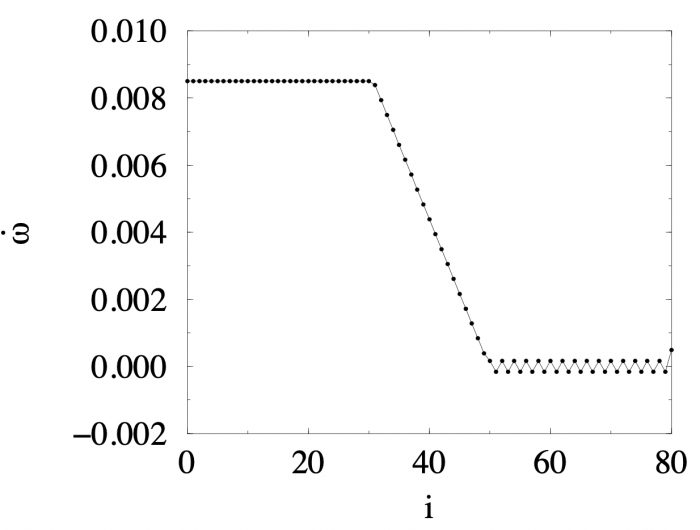

Angular velocities of the particles in a pushed 1D array of 80 particles.

A simple system that clearly reveals the role of particle rotations in the dynamics of granular materials is an array of identical disks (or cylinders) supported by a basal plane and set to motion by applying a constant force on one of its ends. Some aspects of this model were studied in a by Radjai et al. It is numerically shown that with the basic Coulomb’s law of friction, the system self-organizes itself to reach a steady state that is independent of initial conditions. This final state involves a well-defined organization of forces and particle angular velocities, giving rise to (up to three) mesoscopic scales along the array. In the steady state, one can define a global coefficient of friction which is independent of initial conditions but depends on the driving force. The same reference, by an analytical study of the correlations between the rotation modes and the global steady-state friction, shows that even for this regular multi-contact system, the mechanisms leading to an overall friction are quite complicated.

At the macroscopic scale and in the framework of continuum mechanics, the only field needed to describe the elastic deformation of a solid body is the displacement field alone, and the rotations do not appear. They can be computed indirectly from the rotational of the displacement field. Other elasticity theories have been developed in order to account for the rotational degrees of freedom of solid materials, such as Cosserat or micropylar theory. Dimensional analysis shows that an intrinsic length scale has to be introduced. This length may be interpreted as the scale below which rotations can significantly differ from those deduced from the rotational of the displacement field. At a larger scale, the difference vanishes, and thus upon coarse-graining the standard theory is recovered. In the case of granular materials, the discontinuous geometry of the solid phase, and thus of the displacement field, makes it difficult to establish a direct connection between a discrete description at the particle level and a continuum homogenization at a large scale. In the simple array simulations, it is clear that the rotations of individual particles play a determining role for the frictional behavior. Although the framework of the Cosserat theory seems to be more suited to granular materials, it does not appear to provide a simple key to the analysis. Basic questions remain, such as the identification of an intrinsic length scale required by the theory, and which is often postulated to be the grain size.

Further reading:

Friction-induced self-organization of a one-dimensional array of particles

Identification of rolling resistance as a shape parameter in sheared granular media

Nonsmoothness, indeterminacy, and friction in two-dimensional arrays of rigid particles