The micromechanics of granular materials refers to the static and dynamic behavior of granular materials at the particle scale in connection with the macroscopic behavior. Due to granular disorder, a micromechanical description requires a statistical approach. As in a molecular gas, the internal state is characterized by a distribution function of the local geometrical and mechanical quantities such as the contact orientations and forces.

Most micromechanical models are based on a relationship between the force and relative displacement vectors on contact planes or mobilized planes, and a dependence of the parameters on the distribution of contact planes (Christoffersen et al. 1981; Chang and Hicher 2005; Chang et al. 2009, 2011). Such models are conceptually simple, but they capture the main features of the stress-strain behavior in monotonic shearing. An important element of such models is the relation between local and global strain or stress variables. A rational assumption is that the forces on each contact plane are equal to the components of the stress tensor. This is obviously not exact since the contact forces have a highly inhomogeneous distribution. Another possible assumption is a kinematically constrained microstructure in which the local displacements are components of the macroscopic strain tensor. This is equivalent to the assumption that the velocity field has no nonaffine components, which is wrong and leads to overestimated predictions for elastic moduli, for example (Kruyt and Rothenburg 2002). Another constraint used in micromechanical approach is the equality between energy dissipation rate and frictional dissipation at all sliding contacts (Cambou 1993). This is a strong assumption since only a small proportion of contacts are critical and the friction forces have a broad distribution. Furthermore, careful numerical simulations indicate that nearly 25% of energy dissipation in the quasi-static limit is due to inelastic collisions between grains (Radjai and Roux 2004). This energy is dissipated by micro-instabilities during shear, and their signature on the critical- state shear stress can be observed in the form of fluctuations.

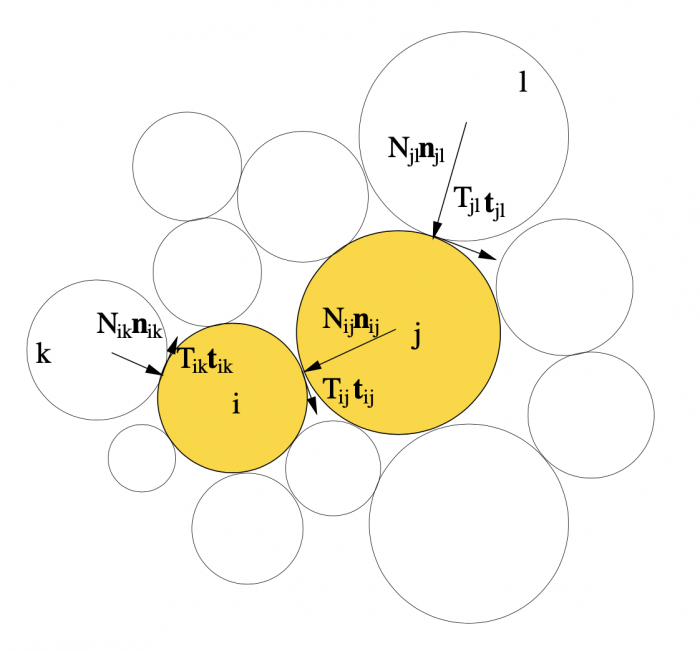

Multicontact interactions: The contact interaction between two particles depends on all other contacts of each particle. The geometrical configuration and dynamics are strongly interwoven.

The current challenge in micromechanics of granular materials is to account for fabric anisotropy, which is required for understanding and modeling complex loading paths (Wan and Guo 2004; Dafalias and Manzari 2004; Li and Dafalias 2015; Radjai 2009; Sun and Sundaresan 2011; Radjai et al. 2012; Chang and Bennett 2015). Because of the problems in the definition of grain-scale kinematics from the boundary or far-field displacements via a localization tensor, there is presently no general expression for the evolution of the coordination number, fabric tensor, and dilatancy. For this reason, most models consider only the effects of geometrical anisotropy by introducing, for example, different elastic moduli for loading and unloading.

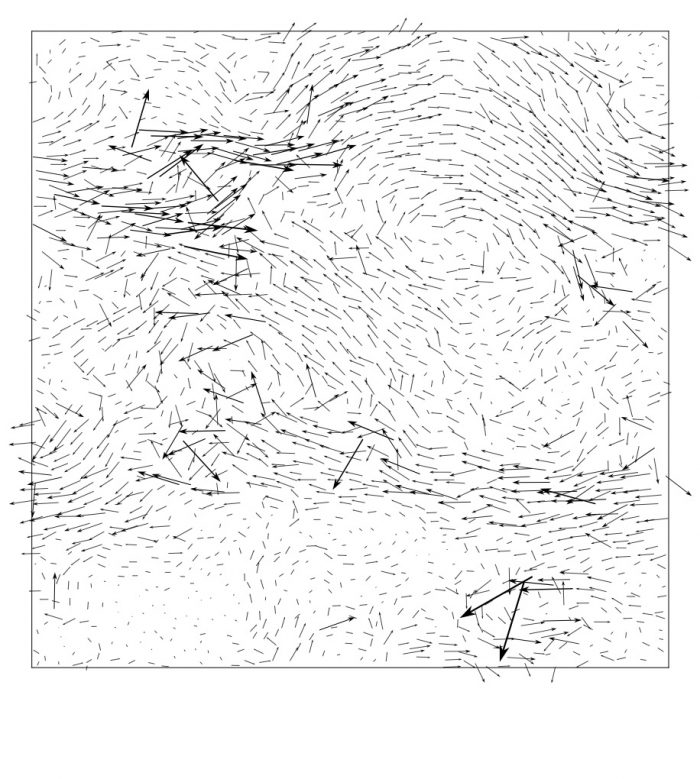

Nonaffine velocity field in granular flows are induced by excluded volume effects. See this reference.

In a constitutive model developed on the basis of monotonic loading behavior or involving no tensorial internal variable, the response upon unloading is elastic. In practice, however, a granular material is fragile in the sense that stress increments in directions opposite to the shear directions cannot be supported without plastic deformation (Cates et al. 1998). This leads to long plastic transients in the new direction when the direction of shearing is changed before the critical state is reached (Radjai and Roux 2004). Furthermore, when shear reversal is repeated at small strains, the system is attracted to a novel state that has not yet been investigated from a micromechanical viewpoint (Alonso- Marroquin and Herrmann 2002). This state is a consequence of subtle memory effects that pull the packing towards a high density but low coordination number.

Further reading: