A. Bignon, M. Renouf, R. Sicard and E. Azéma Nonlinear effect of grain elongation on the flow rate in silo discharge, Phys. Rev. E, 108, 054901 (2023)

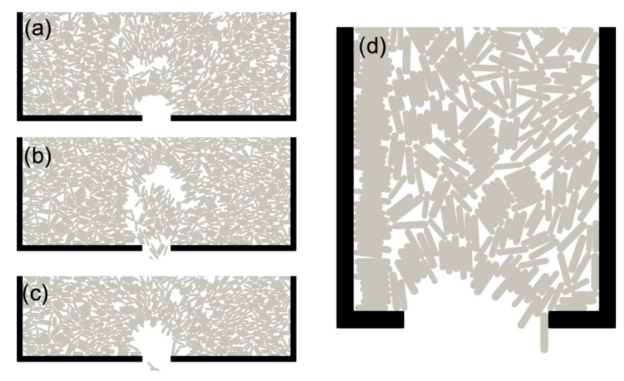

By means of two-dimensional numerical simulations based on contact dynamics, we present a systematic analysis of the joint effects of grain shape (i.e., grain elongation) and system size on silo discharge for increasing orifice sizes D. Grains are rounded-cap rectangles whose aspect ratio are varied from 1 (disks) to 7. In order to clearly isolate the effect of grain shape, the mass of the grains is keeping constant as well as the condition of the discharge by reintroducing the exiting grains at the top of the silo. In order to quantify the possible size effects, the thickness W of the silos is varied from 7 to 70 grains diameter, while keeping the silos aspect ratio always equal to 2. We find that, as long as size effects are negligible, the flow rate Q increases as a Beverloo-like function with D, also for the most elongated grains. In contrast, the effects of grain elongation on the flow rate depend on orifice size. For small normalized orifice sizes, the flow rate is nearly independent with grain elongation. For intermediate normalized orifice sizes the flow rate first increases with grain elongation up to a maximum value that depends on the normalized size of the orifice and saturates as the grains become more elongated. For larger normalized orifice size, the flow rate is an increasing function of grains’ aspect ratio. Velocity profiles and packing fraction profiles close to the orifice turn out to be self-similar for all grain shapes and for the whole range of orifice and system sizes studied. Following the methodology introduced by Janda et al. [Phys. Rev. Lett. 108, 248001 (2012)], we explain the nonlinear variation of Q with grain elongation, and for all orifice sizes, from compensation mechanisms between the velocity and packing fraction measured at the center of the orifice. Finally, an equation to predict the evolution of Q as a function of the aspect ratio of the grains is deduced.