D. Aponte, N. Estrada, J. Barés, M. Renouf, E. Azéma, Geometric cohesion in two-dimensional systems composed of star-shaped particles, Phys. Rev. E, 1009, 044908 (2024)

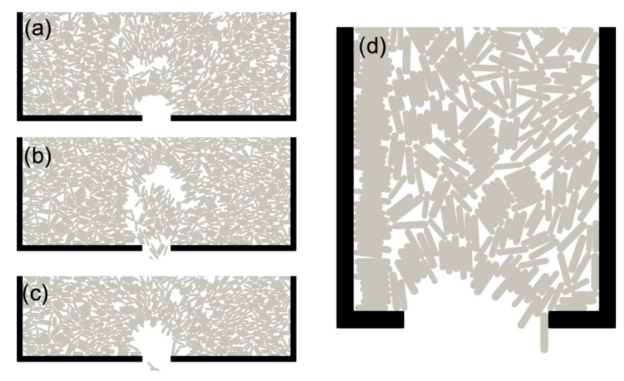

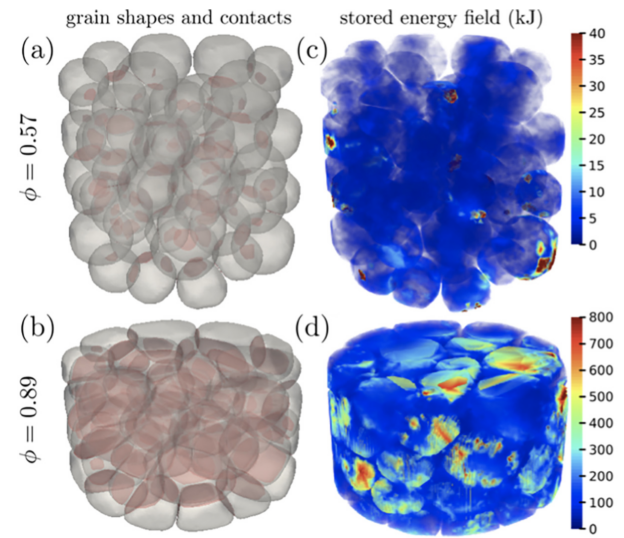

Using a discrete element method, we investigate the phenomenon of geometric cohesion in granular systems composed of star-shaped particles with 3 to 13 arms. This was done by analyzing the stability of columns built with these particles and by studying the microstructure of these columns in terms of density and connectivity. We find that systems composed of star-shaped particles can exhibit geometric cohesion (i.e., a solidlike behavior, in the absence of adhesive forces between the grains), depending on the shape of the particles and the friction between them. This phenomenon is observed up to a given critical size of the system, from which a transition to a metastable behavior takes place. We also have evidence that geometric cohesion is closely linked to the systems’ connectivity and especially to the capability of forming interlocked interactions (i.e., multicontact interactions that hinder the relative rotation of the grains). Our results contribute to the understanding of the interesting and potentially useful phenomenon of geometric cohesion. In addition, our work supplements an important set of experimental observations and sheds light on the complex behavior of real, three-dimensional, granular systems.